Inventory Management Using Machine Learning

For businesses that want to achieve growth, it is imperative to get a grip on the concerns causing hindrance to their inventory management. If a company wants to enjoy high profitability their inventory needs to turn faster. Customers expect speedy deliveries but to achieve customer expectations, businesses need to have the right inventory, at the right place, at the right time. Managing inventory is a complex process and there are many problems but they all do have solutions. Here are some of the most common problems with the inventory management system and ways to handle them:

Problems in Inventory Management

-

Unusual Backorders:

When an order is placed for a product that is not in stock it is back-ordered. If there is no visible pattern or seasonality to the occurrence of a backorder it is very problematic for the supplier as they cannot predict when a backorder could happen. Regular backorders can make customers agitated and look for another supplier leading to loss of sale.

-

Excess Inventory:

The longer an inventory is held on to the more expensive it becomes for the business. To manage excess inventory there is a need for space to keep it, people to manage it and insurance for protection against damage or loss all of which comes at a high cost. All these also take a toll on the company’s balance sheet weakening the inventory turnover ratio.

-

High variation in demand:

The high variability factor in demand for products makes it difficult to gauge accurate inventory needs. It could make the supplier hoard excess inventory on certain days and on other days could lead to being out of stock. Without accurate insights, it’s difficult to predict the variation leading to loss of sales.

-

Short life cycle products:

Some products have a short life span and they need to be handled in a different fashion. If there isn’t enough inventory stocked it could lead to loss of sale and if there is excess stocked then the leftover inventory has to be sold at salvage value.

Problem with the Current Inventory Management System

The current inventory management system lacks in various areas. The ERP system in use has no in-built data visualization template that will enable users to make strategic decisions on Inventory Management, no Cutting-Edge Machine Learning, and Optimization Algorithm which could be used to drive smarter decision-making, and no feature for predictive and perspective analytics.

Why We Need Intelligent Inventory Management System

Smart inventory management can be described as an innovative way to use data and powerful software in order to better control costs and fill rising demand with less inventory. Inventory control procedures can help to improve inefficiencies and even maximize profits. A smart inventory management system can lead to a higher inventory turnover ratio, therefore increasing one’s profit margin. It can also automate repetitive tasks, thus saving a significant amount of time and money.

Our Product Features

- Inventory Profiling Dashboard and Optimization

- Inventory Prediction

- Backorder Prediction

- Using Machine Learning to Prescribe Inventory Level

Inventory Profiling Dashboard and Optimization

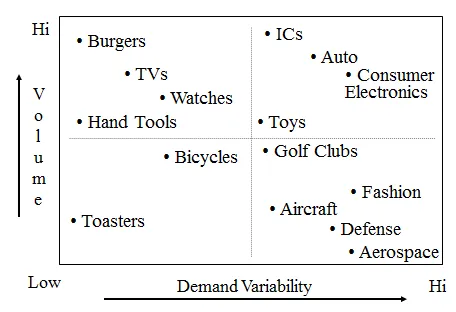

Profiling of inventory based upon their characteristics involves both quantitative and qualitative forecasting. But, demand planning requires a holistic process.

Stock Keeping Units need to be profiled based upon their characteristics such as volume and variability in order to determine the appropriate treatment.

Source: Resource Systems Consulting, Blog: Demand Segmentation Definition

Applying Different Inventory Optimisation-techniques to Different Segments

- News-Vendor Model – The news-vendor model is a mathematical model in operations management and applied economics used to determine optimal inventory levels. It is characterized by fixed prices and uncertain demand for a perishable product. This is mostly used for short life cycle and perishable product

- Order Upto Model – Order up to level model is used when stock levels are periodically reviewed and an amount of the item is ordered to return stock levels to the target level.

- Optimal Order Quantity – The optimal order quantity, also called the economic order quantity, suggests the accurate quantity of product to be purchased at a given time. The process includes calculation of Optimal Quantity, Safety Stock and Reorder points, etc.

- Stochastic Optimization – Stochastic optimization (SO) methods are optimization methods that generate and use random variables. For stochastic problems, the random variables appear in the formulation of the optimization problem itself, which involves random objective functions or random constraints.

- Multi-Echelon Inventory Optimization Algorithm – Multi-echelon inventory optimization determines the correct levels of inventory across the network based on demand variability at the various nodes and the performance (lead time, delays, service level) at the higher echelons.

Generation of an Inventory Dashboard

- Inventories are profiled based on their characteristics such as volume, coefficient of variation, life cycle, intermittency, etc.

- For each segment, a different inventory optimization technique is applied

- Various charts can be formulated which would take into account lead-time, pipeline inventory, demand forecast, actual sales, on-hand inventory, on-order inventory, backorder, etc.

Inventory Prediction

Inventory Prediction is a method in which you calculate the inventory required to fulfil future customer orders considering the amount of product you can produce at a specific time. This process requires analysis of historical sales data, planned promotions, and other external forces.i

Benefits of Inventory forecasting include:

- Need for less inventory on hand

- Increase of fill-rate

- Better Return on Inventory

- Reduced Inventory cycle time

Advanced machine learning models predict inventory level based upon climate data, freight data, supplier data, and demand data.

Backorder Prediction

We have described what a backorder is towards the starting of this blog. With machine learning, we can identify hidden patterns and predict inventory backorder in the future.

Benefits of backorder prediction:

- Protects customer base

- Responsive supply chain

- Risk Management

Advanced machine learning helps identify patterns and behaviors and predict unusual inventory backorder.

Inventory Ordering and Management using DNN and Reinforcement Learning

One of the major dilemmas for retailers is managing the inventory of short life-cycle products. The main issue is that if you are storing too much of such a product, it will lead to a high ordering cost, production cost, holding cost, damage cost, as well as a loss due to price markdowns at the end of the sales season.

Deep Neural Network as a solution:

Using cutting-edge deep neural networks, we have developed an algorithm that can accurately predict and suggest the optimized inventory level for which the profit will be maximized. The algorithm uses a multi-feature news vendor optimization model as a cost function.

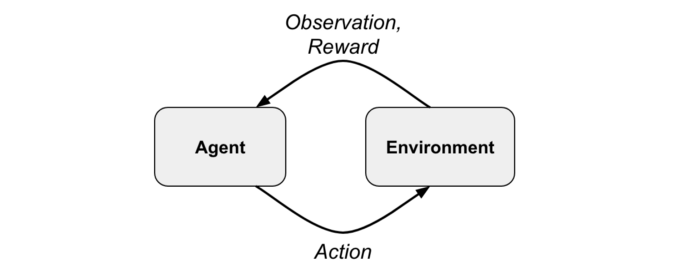

Inventory Ordering Using Reinforcement Learning

Reinforcement learning can be thought of as an agent interacting with an environment. The agent performs actions, receives rewards, and builds up a picture of the environment as well as how its actions affect the environment through observations.

The key element of reinforcement learning — and what makes it different from other machine learning methods — is that learning occurs through an interaction loop where the agent learns which actions lead to high or low rewards, given its current state. In this way, learning equates to an agent attempting to maximize its expected future reward. i

ii

ii

Using this concept, we have created a smart inventory ordering bot that can produce orders that lead to a minimum inventory level in the warehouse as well as a maximization of sales.

Stay tuned with our next blog article.

Get in touch with IT Action Group today.

Reference:

iLopienski, K., Written by: Kristina LopienskiKristina is the Head of Content at ShipBob, & Kristina LopienskiKristina is the Head of Content at ShipBob. (2020, July 29). Inventory Forecasting: Best Practices for Your Business. Retrieved August 31, 2020, from https://www.shipbob.com/blog/inventory-forecasting

ii McMahon, A. (2018, May 30). Reinforcement Learning in the Supply Chain. Retrieved August 31, 2020, from https://medium.com/streamba-data/reinforcement-learning-in-the-supply-chain-2fd56ab59c2e